AI in Manufacturing

The manufacturing industry is undergoing a revolution driven by the need for efficiency, reduced downtime & improved quality control. Manufacturers face challenges such as equipment failures, quality assurance & continuous monitoring leading to operational delays & higher costs.

However, the implementation of AI can help address these challenges by enabling robust and automated inspection, monitoring, and predictive maintenance of machinery.

Why Renumics

We Have The Technology And Industry Knowledge

At Renumics, we combine state-of-the-art AI technology with our expertise in the manufacturing industry to develop AI-driven systems for predictive maintenance, monitoring, and inspection.

Through various business and research projects, our team of AI experts has gained valuable insights into the industry.

We provide AI solutions that enhance manufacturing efficiency and accuracy for in-line and end-of-line settings. Our technology stack includes robust automated visual and audio inspection, object detection, and machine monitoring to ensure consistent product quality and work safety while minimizing downtime.

- Detect errors early

Use AI to detect defects and errors in manufacturing early and save costs.

- Reduce downtime

Integrate AI-driven predictive maintenance to minimize downtime and improve the quality of your production.

Discover the Beneftis of AI for the Manufacturing Industry

Explore use cases for AI in the manufacturing industry and find out how Renumics can assist you. We are your ideal partner for industrial AI.

Avoid Unforeseen Failures

Anticipate and Prevent Production Downtime

Data-driven predictive models can be used to identify patterns in machine data that indicate an imminent failure before the effects on the manufactured product become visible. By monitoring and analyzing the machine data, strategic decisions can be made regarding the maintenance of the production line and serious production faults can be detected before the first defects appear on the product.

However, implementing production-ready AI systems for predictive maintenance is challenging due to the dynamic production environment and high demands on KPIs, as business decisions are consequential.

Our team is experienced in handling complex sensor data from various sources for predictive modeling. Our concepts are developed for production environments and include robust anomaly detection and strategies to adapt to different operating modes.

- Make Use of Machine Data

Detect anomalies and imminent failures and prevent production downtime.

- Predictive Maintenance

Improves equipment reliability, extends lifespan, and enables proactive maintenance planning.

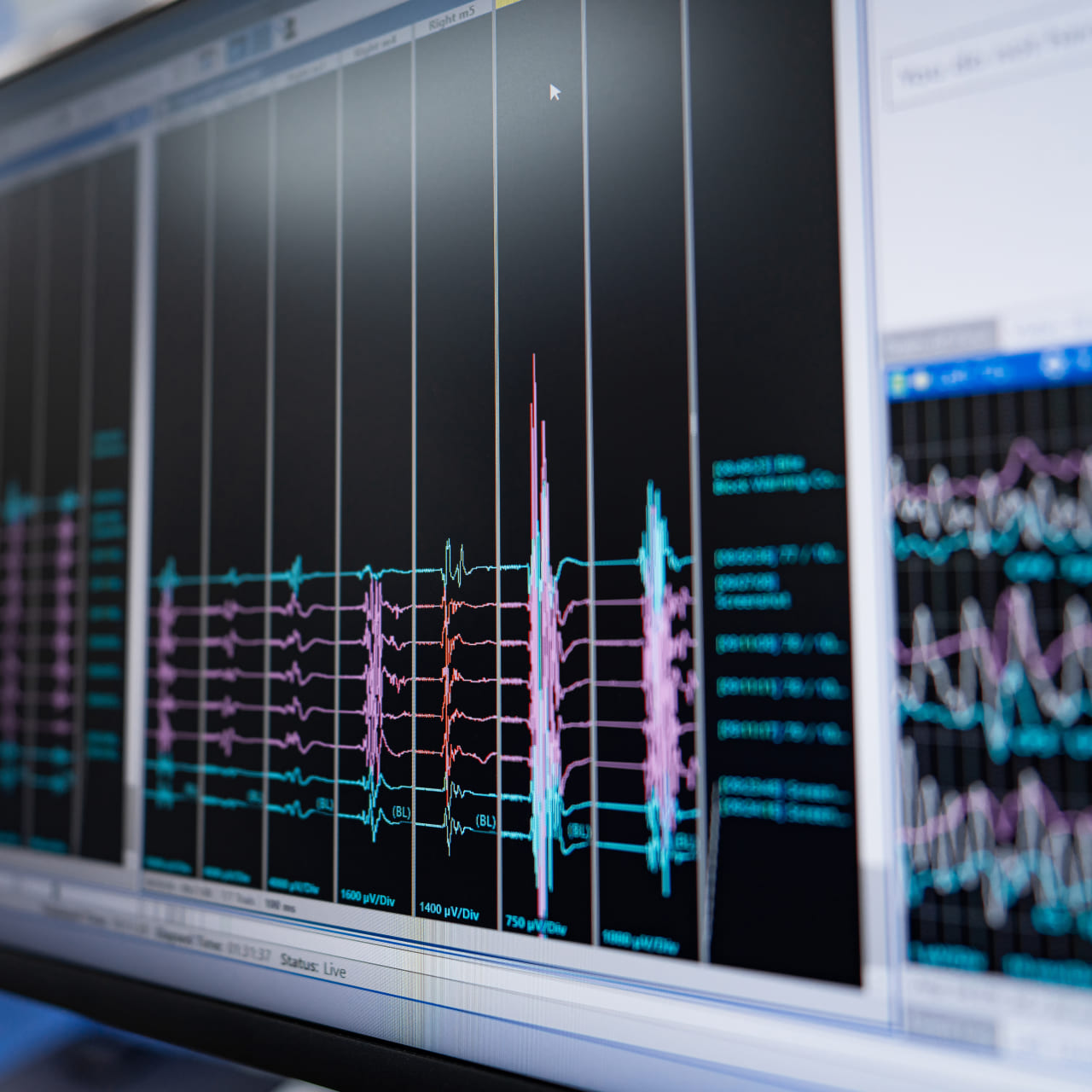

Vibrations, Acceleration, and Noises in Machine Data

Acoustic Event Detection & Anomaly Detection

Automatically detecting and analyzing acoustic events plays a crucial role in ensuring operational efficiency and safety. With the help of advanced technologies such as audio transformers, acoustic event detection has become a mature technology that enables monitoring and evaluation of noises and vibrations produced by machinery during operation.

Renumics utilizes event and anomaly detection techniques, paired with audio classification to build robust and trustworthy applications for predictive maintenance with acoustic data.

Read more about Acoustic Event Detection and other Manufacturing Use Cases in our Blog.

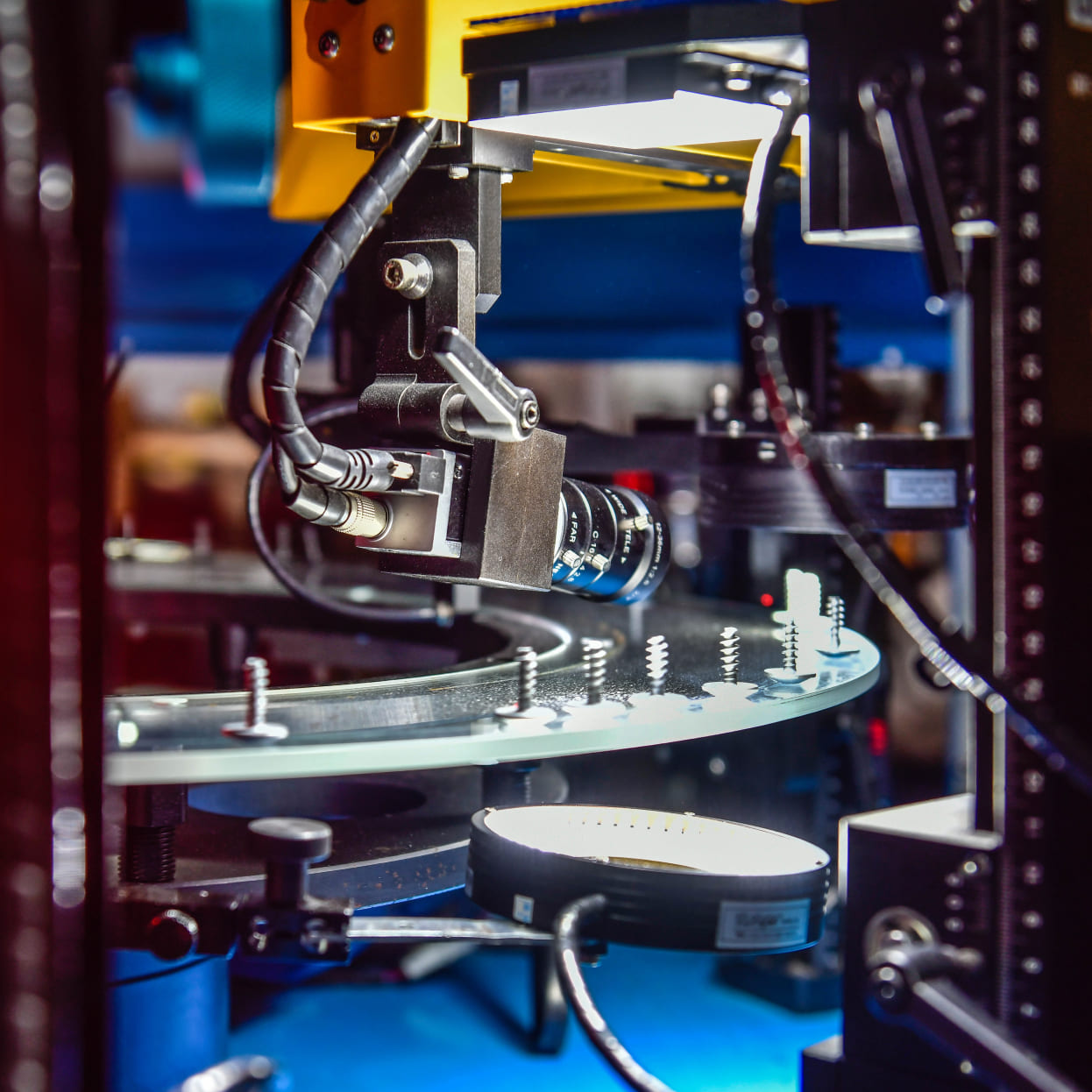

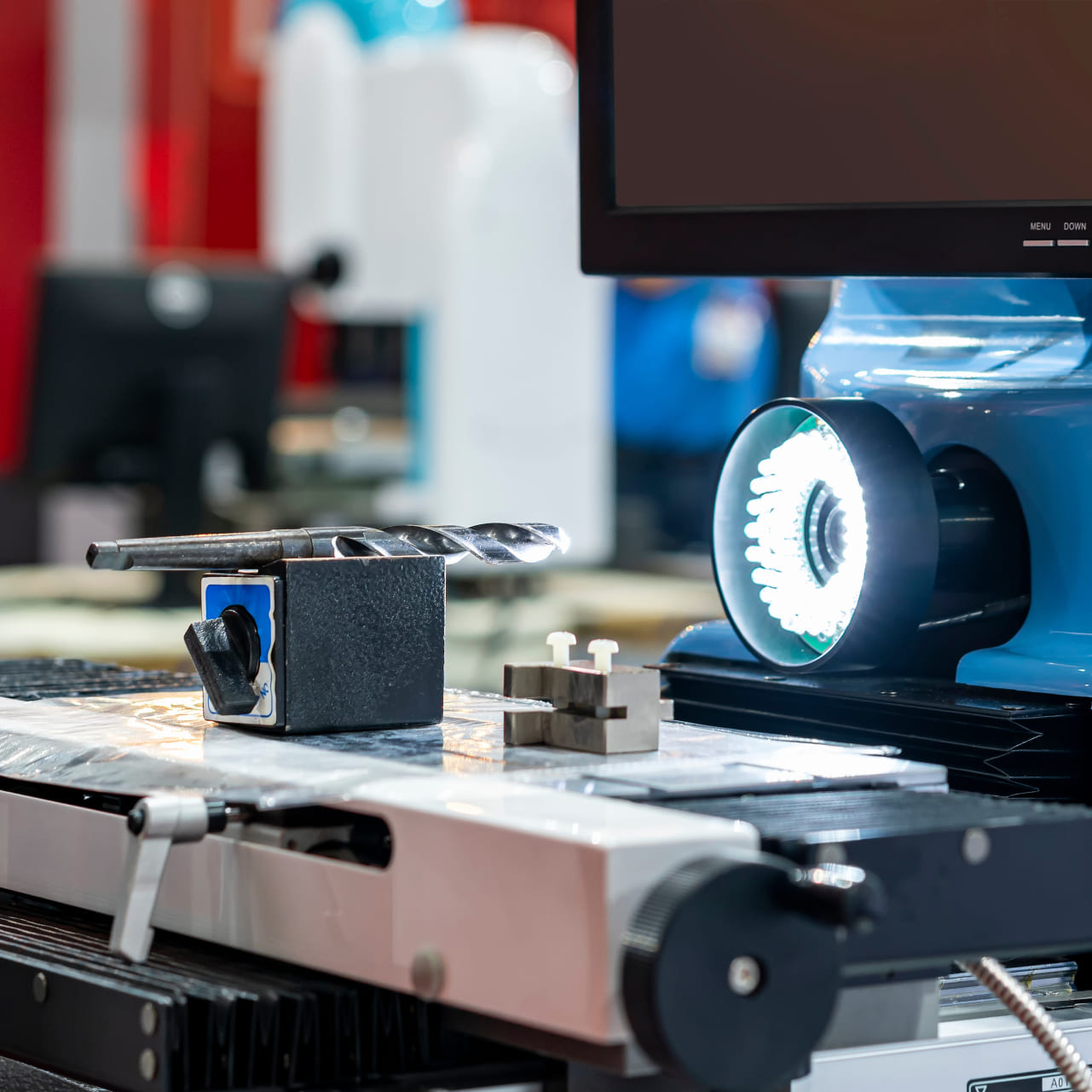

Automated Visual Inspection in Production Line

Modern computer vision methods in combination with high-speed camera setups are widely spread for visual inspection in industrial settings. Integrating AI into visual inspection can result in significant improvement by reducing susceptibility to issues like light, reflections, and dirt that may arise due to manual manufacturing steps.

With new advancements in technology, machine learning models can already be fine-tuned with a few samples, which offers great adaptability and flexibility to accommodate design changes.

- Automated detection of errors

Reduce production costs and waste through early detection of faulty parts in the manufacturing process.

- Not just a blackbox: get explanations for decisions

Techniques for explainable AI allow you to understand the decisions of the AI system.

Avoid Expensive Sample Collection

Training Machine Learning models requires a specific amount of samples. In the industrial context, collecting samples seems easy but obtaining parts with defects or anomalies are expensive to gather. Annotating samples by domain experts may be even more pricy.

In this case, synthetic data can be used to save time, effort and costs and reduce bias in datasets. Although, synthetic data does not come without costs since significant effort in guiding and controlling the generation process and identification of biases and error types (anomalies) in the real-world data must be done.

At Renumics, we have extensive experience in data curation, data cleansing and control and selection in the synthetic data generation process. Our methodology for training machine learning models relies on a data-centric approach. We prioritize the performance of the AI system in real-world applications, rather than just the machine learning model in a theoretical setting.

For more information about our data-centric methodologies, please refer to our Blog and Playbook.

Object Detection for Production Line Environments

Utilize AI systems to improve surveillance and safety in your production line setup. Object detection can be used as technology to consistently monitor the environment and instantly detect any unexpected objects or obstacles that could disrupt the workflow or pose safety hazards for production.

- Operational Efficiency: Remind your employees when stock is low

- Proactive: Ensure that routes are not blocked

- Enhances Safety: Hold machines if objects are located in hazardous areas

Stay Updated!

Be up to date with manufacturing use cases and content from Renumics. Take the chance and subscribe to our newsletter.